- #Service wire for 100 amp panel how to

- #Service wire for 100 amp panel install

- #Service wire for 100 amp panel code

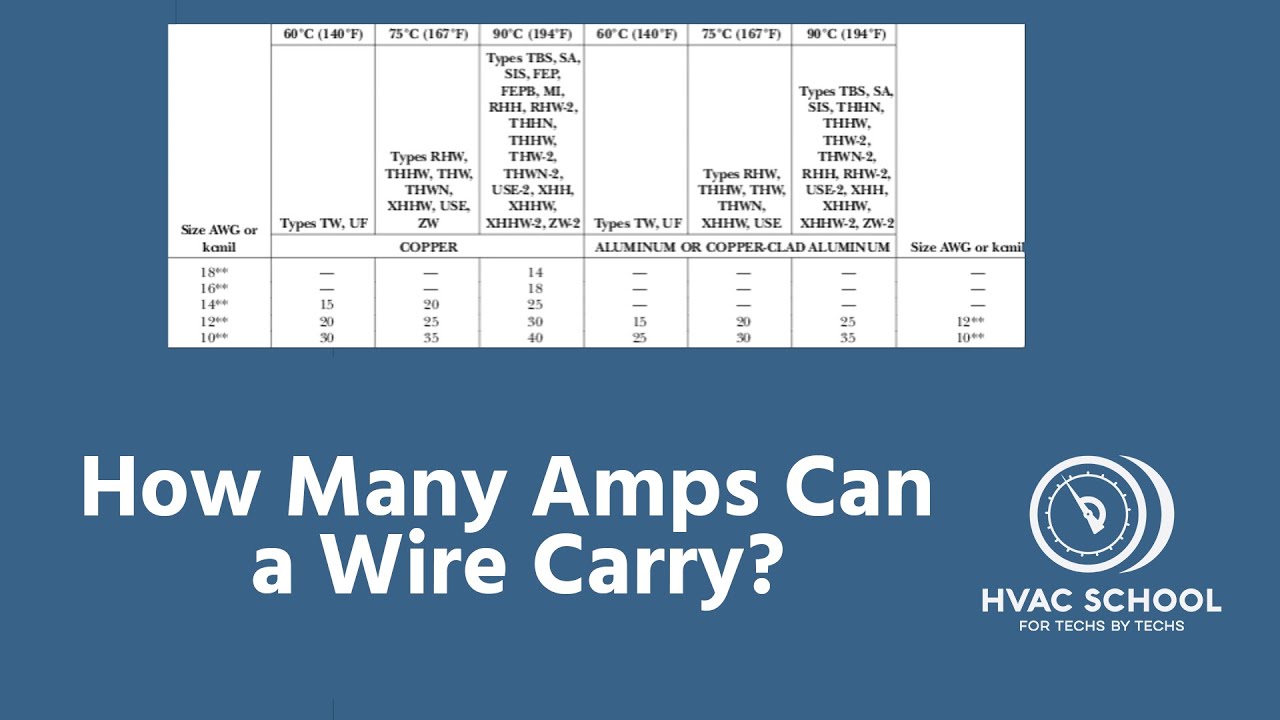

The Biggest Mistakes DIYers Makeand How to Avoid Them. For example, a 100-amp service panel could have circuit breakers that add up to more than 200 amps. The total might be more than twice the total amperage of the box. Given the situation youre in, youll want to use a 100A main breaker panel (you can get larger busses, but you need the main to be 100A in this case) for this job. Add the amperages of all the individual breakers in the box. So pay a consulting fee or buy a case of beer or a jug of hooch for a licensed local electrician to line out your project for you. Finally, we land the incoming secondary wires from the load-end transformer on the main terminals of the loads distribution panel. You want to pass your inspection first time around but without spending more money and time than you have to. You need good advice before making electrical mods. My friends here in PM wish you well and would never knowingly mislead you but few of us (including me) are electrical professionals. While this is presented in tables, an informed judgement is still required.

#Service wire for 100 amp panel code

OTH a 100 Amp service is defined by the breaker and the conductors it feeds have to meet code requirements for Ampacity, conduit fill, insulation, placement in construction, max ambient air temp, and other factors. If you’re a layperson, you will take several considerations into account before answering this question, including: 1). In electrical practice the overcurret protection is intened to protect the conductors it feeds not the power consuming equipment. The size of ground wire for 100 amp service is 8AWG or 6AWG. #4 may be technically adequate for your immediate application for a 100 Amp service for equipment that's seldom run to capacity but when feeding a pump or a heater for example #4 may not be suitable. Look up accaptable ampacity in the NEC and your local code for your application. They're satisfactory in most situatations but not always suited to every application. Remember NEC and local code represents minimum standards. Then consider conductor size and conduit size. Some jurisdictions require upgrading of the branch circuit or sometimes even the whole system if any parts is sub-code. Maybe not in Wisconsin but certaily in warm climates. Some jurisdictions have more stringent requirements for conductor ampacity and other electrical minutia.

I started with just agreeing to dig the trench for the 100 amp w.

#Service wire for 100 amp panel install

This isn't a standard conductor size though, so we should use a 6AWG copper conductor (which has 13.30mm2 of area) or a 4AWG aluminum conductor for this ground wire.FIRST!!! Check local code. At first, I wasnt sure if I could complete the wiring and install of the 100 amp sub panel. Multiplying that by the 8.367mm2 area of an 8AWG copper conductor gives us about 10.55mm2 for the resulting wire. the 1AWG that is required to meet Code ampacity rules gives us a size ratio of 53.49mm2/42.41mm2 based on the NEC Chapter 9, Table 8 conductor sizes (we can do this math in mm2 since the conversion factors cancel out here) or about 1.26. Size proportionately, according to the circular mil area of theįor instance, using 1/0 aluminum wire for the hots and neutral in your example vs. Grounding conductors, where installed, shall be increased in Increased in size from the minimum size that has sufficientĪmpacity for the intended installation, wire-type equipment When you start upsizing wires for voltage drop control, the size of the ground wire is governed by NEC 250.122(B): If you are using a four-wire direct burial cable, then just use the ground wire in the cable as it will be quite amply sized for the job it is doing if you are using PVC conduit, then bare 8AWG copper would be my choice to keep conduit fill down.and then upsize from there based on how much upsizing of the other wires you do You are correct that for a 100A feeder, the associated ground wire needs to be an 8AWG copper or 6AWG aluminum wire. Siemens Outdoor Sub PanelHow to Install and Wire a Sub Panel SgtDonovan 59K subscribers Subscribe 16K 890K views 1 year ago In this video, I show you how to.

0 kommentar(er)

0 kommentar(er)